For an even better result in execution and end result, it was especially paid attention to some details.

Here we go:

Start:

First, the axle shafts and the starter were removed:

Then the electrical wires, the gearbox holder, the coupling cable and the connecting screws of engine / gearbox:

The gearbox could then be removed:

The removed gearbox was attached to the gearbox holder:

The removed parts were cleaned and placed aside. The new Quaife Limited Slip Differential is already ready:

The cover of the 5th gear has been removed:

The 5th gear pair and the associated shift fork were removed:

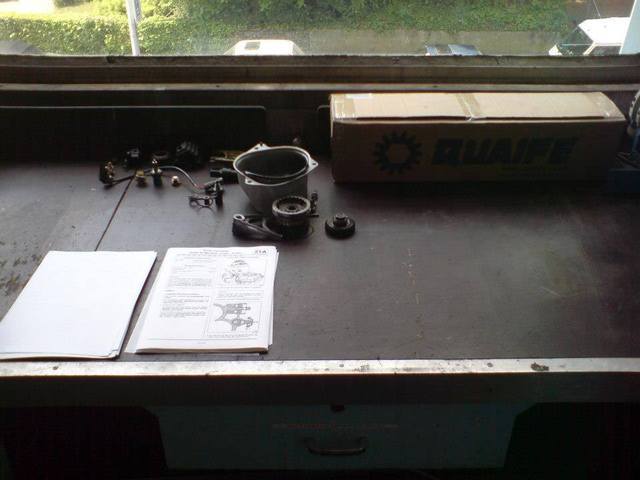

The table fills with parts:

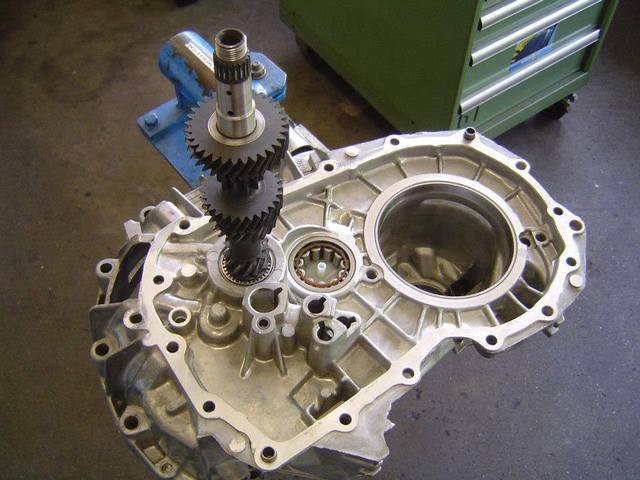

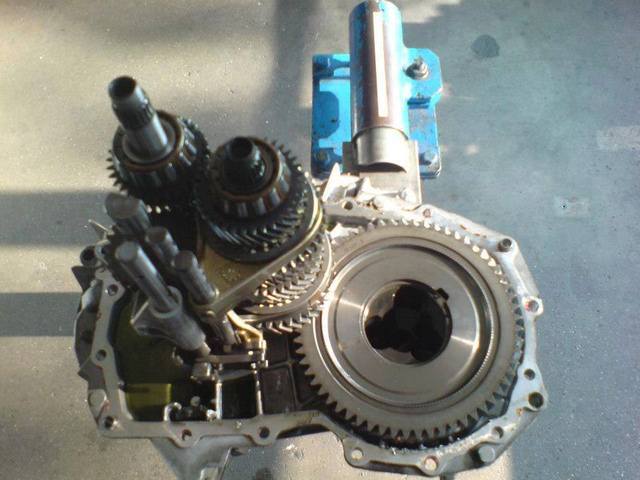

The gearbox housing was removed:

The shafts were expanded. Also the switching parts:

he clutch actuation has been removed:

The removed parts:

The original differential was developed:

All parts were cleaned:

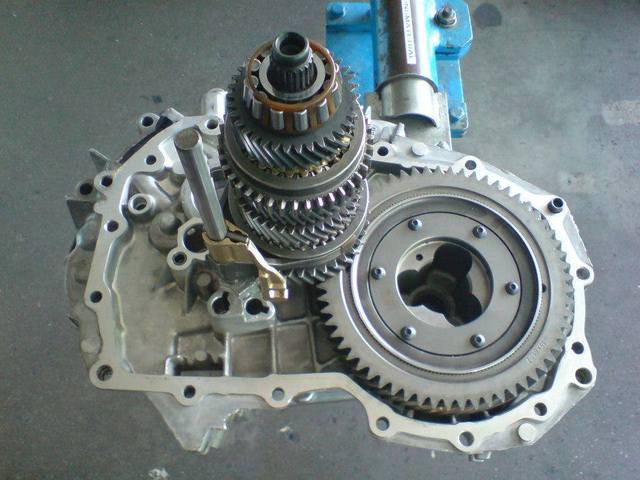

New roller bearings for the secondary shaft were mounted:

The new bearing ring for the secondary shaft was mounted:

The new bearing ring for the secondary shaft was mounted:

New roller bearings for the primary shaft:

The new roller bearing for the primary shaft was mounted:

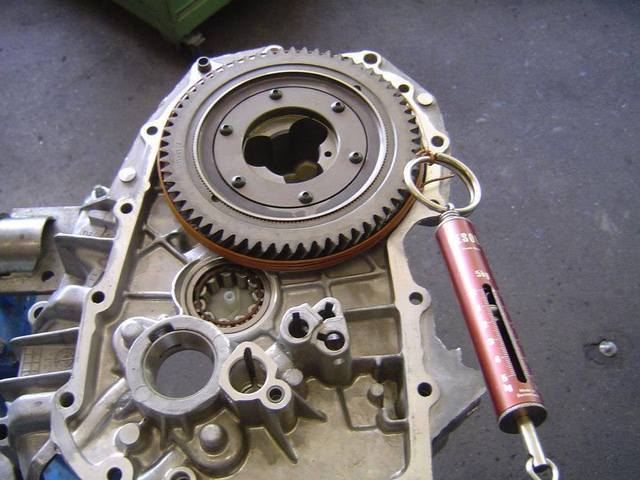

The crown wheel had to be pressed from the original differential and pressed onto the Quaife ATB Limited Slip Differential:

The crown wheel is now pressed onto the Quaife ATB Limited Slip Differential:

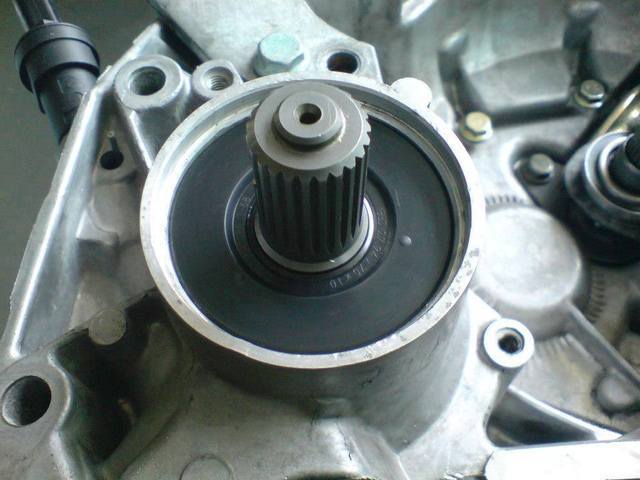

Detail view:

The tacho drive was installed:

The transmission housings were glass-blasted:

A new roller bearing for the secondary shaft was pressed into the gear housing:

The roller bearing was pressed in:

Detail view:

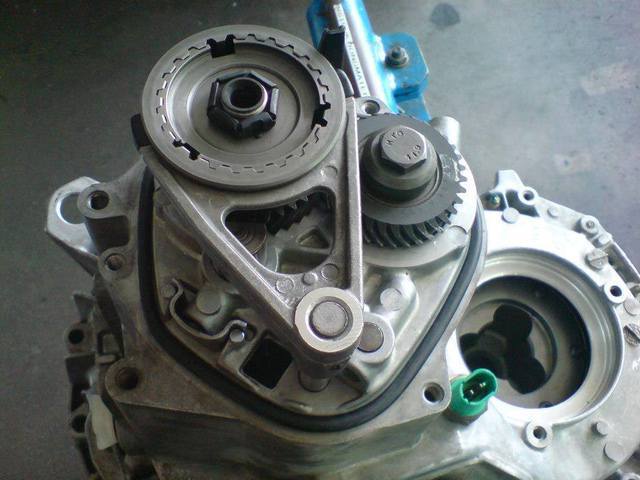

The new bearing shell for the primary shaft was pressed into the gearbox housing:

The bearing shell was pressed in:

New roller bearing for the Quaife ATB Limited Slip Differentiall:

The bearing shell of the differential bearing was pressed in:

Detail view:

The roller bearing was pressed onto the Quaife ATB Limited Slip Differential:

The roller bearing was pressed on:

New roller bearings for the transmission housing for the primary and secondary shaft:

The bearing shells were pressed into the gear housing:

The bearing shells were pressed in:

Detail view:

New bearings for the shift actuator: